Expansion Allowance:

Before loading commences, consideration must be given to the temperature of the cargo being loaded and to the maximum temperature, which may be expected on the voyage. Where there is a possibility that the cargo temperature will rise during the journey, sufficient ullage space must be left to allow, with safety, the increased volume of cargo resulting from expansion.

Spot checks of the cargo density and temperature must be taken with the ship's equipment using a sample drawn from the ship's manifold and the result recorded in the Cargo Log Book. These checks are essential to provide early warning of problems with density, temperature, or even grade of the cargo.

Cargo heating planning and optimisation

Different oil cargoes such as special oil products, special crude oils, heavy fuel oils, etc. may require heating in particular in winter and cold climate regions. Some of this heat required can be supplied by the exhaust gas economizer. However, in many cases, an additional auxiliary boiler is needed to supply sufficient steam. Steam from the exhaust gas is generally sufficient to heat the heavy fuel oil that is used on most ships; in port, however, steam from an auxiliary boiler may be needed.

For cargo heating purposes and to reduce fuel consumption and heating costs, a voyage-specific cargo heating plan should be developed by the shipboard team with support from the head office's operation department. For a proper plan, the following should be considered:

- Vessel tank configuration.

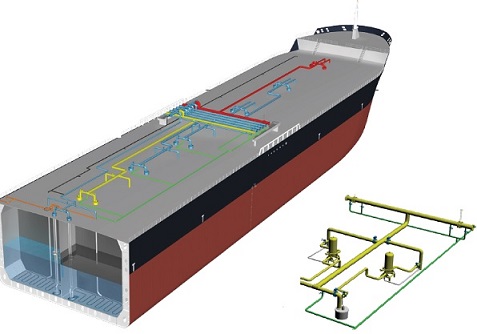

- Whether deck heater or tank heating coils are provided.

- Number of heating coils and surface areas.

- Cargo details including specific heat, pour point, cloud point, viscosity, and wax content.

- Weather en route including ambient air and seawater temperatures.

- Estimated heat loss and drop in temperatures.

- Recommended return condensate temperatures.

- Estimated daily heating hours and consumption.

Various parameters such as daily air/sea temperatures, weather, cargo temperatures at three levels, steam pressures, return condensate temperature, actual against estimated consumptions, and temperatures are discussed between the shipboard team and head office. The heating plan should be reviewed and revised appropriately throughout the voyage.

The optimum temperature to which cargo should be heated for carriage and discharge largely depends on the following factors:

- Pour point: It is the lowest temperature at which the liquid will pour or flow under prescribed conditions. It is a rough indication of the lowest temperature at which cargo is readily pump-able. The general principle is to carry cargo at ten 0C above pour point temperature.

- Cloud point: It is the temperature at which dissolved solids are no longer completely soluble, precipitating a second phase and is synonymous with wax appearance temperature. Once separated, it requires temperature over 80 0C to dissolve the wax. Cargo temperature should not be allowed to fall below the cloud point.

- Wax content: High wax crude tends to deposit sludge, and therefore require to be maintained at a higher temperature to prevent wax fall out.

- Viscosity: High viscosity oils do not necessarily deposit sludge and may be carried at lower than the discharge temperatures. However, for discharge purposes, the heating will be done to reduce the viscosity to acceptable levels for cargo pumps.

- Ambient weather and sea conditions: This will also influence the cargo carriage and discharge temperatures as these impacts the level of heat transfer from cargo tanks or fuel tanks.

The cargo heating plan would need to take into account the above parameter. As part of cargo heating planning, relevant instructions will be developed. Heating instructions should be reviewed after loading cargo based on the charterer requirement. Permission to carry and discharge the cargo at optimum temperatures should be requested from the charterer or cargo owner. The heating plan should be made soon after loading cargo and reviewed/updated daily considering the various factors that affect the heating and customer requirements.

A review of the heating log abstract with the following will help with better future planning and identifying the gaps:

- Actual vs. planned temperature

- Actual vs. planned fuel oil consumption

- Actual vs. planned heating hours

Vessels should complete the heating abstract (daily basis) after completing each voyage, send it ashore along with the Cargo Heating Log, and identify any gaps.

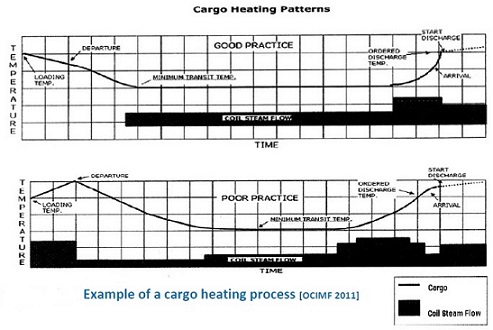

Figure shows a typical cargo heating patterns graph.

Figure - Example of a cargo heating process [OCIMF 2011]

Operational control and best practice

For best practice cargo heating planning, the following should be noted:

- Vessels should have a greater understanding of the voyage manager/charterer's heating instructions.

- Seek the receiver/charterer's permission for allowable range of cargo temperatures.

- Avoid heating during adverse weather period.

- Create and follow the proper cargo heating plan to verify the effectiveness of actual heating progress.

- Closely monitor and analyse cargo heating reports. Monitor heating daily to address deviations from the heating plan.

- Do not heat for short frequent periods and running boiler at low loads.

- Follow the recommended condensate temperature and optimum boiler settings for efficient cargo heating. Heating instructions, accompanying the heating plan, should further highlight these points.

- Maintain efficient and good communication between the vessel and the voyage manager/charterer about the plan and execution.

Cargo heating may also benefit from the use of effective insulation. For example, using lagging on heating coil water/condensate return pipes and steam, thermal oil, and hot-water lines on-deck area. This could be a significant energy-saving option as it has been observed that some ships lack

the insulation of branch lines and cargo tanks. The insulation material must be of good quality. A poor quality of insulation material is likely to rot or lose its effectiveness.

Loading And Carriage Of Low Temperature Cargo

Increasingly export of products from ports exposed to shallow ambient air temperatures is occurring. Due to the transport and storage time, the cargo temperature can be close to the ambient temperature, and the terminal may have no means to heat the cargo.

The loading and carriage of low-temperature cargo requires careful Risk Assessment which should be commenced when the vessel is proposed for loading at such a terminal.

Discharge ports may also have a minimum acceptable cargo temperature which could be close to 0 deg C.

Oil tankers are not specifically designed to load cargo at shallow temperatures. It is generally constructed of grade A steel, which is not charpy tested / of low toughness and could be subject to increased risk of brittle fracture at low temperatures. Three factors have to come into play simultaneously to experience a brittle fracture:-

- Initial crack / defect

- Temperatures low enough such that the material is brittle

- Loads on the structure

The cargo of temperature to 0 deg C is considered acceptable to load by most classification societies. Loading of the cargo of temperature down to -10 deg C should not normally present an unacceptable risk. However, it is outside the criteria specified by class, and therefore class must be consulted. Loading cargo with a temperature below - 10 deg C shall not be undertaken without careful consideration of all the risks due to the increased possibility of brittle fracture. In all cases where cargo below 0 deg C is to be loaded the Ship Management Technical Office must be advised.

Loads on the Structure

If the cargo temperature is below -10° C and the vessel is not specifically built for carriage of cargo at this temperature great care must be taken to ensure that loads on the structure during cargo operations and during passage are minimised. This may require the vessel to consider waiting in sheltered waters for a weather window on the loaded passage.

Equipment

All equipment shall be in good order and suitable for the expected cargo loading temperature, checks are to be made with manufacturers where required -

Cargo / Ballast tank coating temperature tolerance.

Cargo tank temperature and high level/overfill sensors.

All instrumentation associated with deck heaters.

• Ballast valves were not submerged in ballast must be regularly worked to prevent freezing.

• The material of the piping system, couplings, cargo pumps, valves, seals, and instrumentation. Valves on deck should be thermally insulated / trace heated to prevent them becoming inoperative due to ice formation and clogging.

• Cargo tank pressure relief arrangements must be suitable for the temperatures involved, trace heating applied / procedures in place to ensure continuous freedom to operate put in place.

The risk of fracture of equipment due to volumetric expansion of ice is always present.

All the above shall be considered as part of the risk assessment for the operation.

Also, consider safety precautions for Ballast operations in sub-zero temperatures.

Cargo system preparation

The cargo tanks, pipelines, heating system and all associated instrumentation shall be completely free of water before entering the cold weather area, any water present in cargo tanks will freeze immediately the cargo loading is commenced.

Cargo heating

If loading of low-temperature cargo is to proceed, then measures to increase the cargo temperature need to be implemented to reduce the vessel's exposure to brittle fracture during loading and on the route and further to make the cargo temperature acceptable to the receiving terminal.

The Reid Vapour Pressure, Flashpoint, and Boiling Point of the cargo must also be considered concerning cargo volatility. Overheating of the cargo due to insufficient circulation, cargo pump failure, etc. must be avoided and shall be considered in the risk assessment. Other hazards that must be controlled are freezing the heating medium and excessive ice build-up in ballast tanks.

Reduced / low cargo filling rate

A low tank filling rate will reduce cargo thermal inertia and affect the structure and allow any cargo heating up from the ballast to have more effect. Depending on the ballast water temperature the cargo temperature rise can increase by 0.5 deg C / hour, however, obviously, the rate slows down as cargo mass increases.

Use of ballast water to slowly heat the cargo

This method is preferred and safest for cargo with a low flashpoint and boiling point < 140 deg C. Where possible, and as far as practicable concerning stability and stress considerations. The ballast should be retained to the draft level to avoid freezing, which will occur if the level is kept above the waterline. Ballast tanks are acceptable as a heating source provided that ice accretion on the ballast tank bulkheads does not exceed 10% of the ballast tank width or height for double bottom tanks. If 10% is exceeded, the ice layer will act as an insulator. If ballast tanks are provided with a heating system / or bubbling system, this must be kept in operation to reduce icing. To assist the process the cargo shall be circulated within the tank.

Ship's Experince Factor (SEF OR VEF)

Surveyors at a load port must always be given the information to calculate the Ship's Experience Factor or Vessel Experience Factor.

Fire-Fighting Precautions at the Manifold

Before any loading or discharging operations are commenced, the following fire-fighting equipment is to be placed on deck in a position approximately 10 meters forward or aft, but always upwind of the manifold:

- One portable foam-making branch pipe with eductor, connected to a fire hose and hydrant.

- Not less than 75 litres of foam compound.

- An additional hose with jet/spray nozzle attached, and connected to a hydrant.

- An International shore connection and fire plan/wallet are to be available, situated in the vicinity or point of access to the vessel.

- A semi-portable Foam or Dry Powder extinguishers is positioned close to the manifold, or if semi-portable extinguishers are not available, then two 9 liter foam extinguishers are to be used. The oil spill materials are to be kept available for use in the event of spillage but are not to be placed adjacent to the fire-fighting equipment.

- The equipment mentioned above is to be provided from the nearest Supplementary Equipment Station and Oil Spill Response Centre.

- 75 liters of foam compound will be consumed by anyone branch pipe in 5 minutes. If the Master considers that the Emergency Organisation will require more than 5 minutes to supply additional foam compounds to the manifold area, additional 25-liter canisters will be positioned in readiness.

- The fire main must be pressurised throughout cargo operations.

Bunkering Operation

The Shore Facility’s permission must be obtained prior to carrying out bunkering during cargo oil transfer operations.

Preparation of Main Engine

The main engine must always be ready for immediate use in case of an emergency during cargo oil transfer operations.

Measures during Extreme Weather

The criteria for stopping of cargo operations and dis-connection should be agreed and listed out in the "Ship / Shore Safety Checklist" as to be within the standards, as mentioned in the final handbook.

When the vessel is moored alongside a pier or a buoy and extreme weather with a wind velocity exceeding 40 knots, adverse currents, or the like, the Master should consider shifting the vessel into safe waters. Such should be carried out well in advance, after consultation with the terminal.

If natural catastrophes like hurricanes, tsunami (tidal wave), or earthquakes are predicted, the Master should consider leaving the port to seek shelter in safe waters.

If it is not safe to leave the port, new mooring ropes must be paid out to ensure that the vessel is always moored safely at the berth.

Master shall consult terminal in all such conditions & terminal standards to be followed.

Restrictions on Use of Fire, smoking, and other General Precautions to the Crew

All personnel must comply with the procedures in accordance with the general precautions onboard Tanker .

All crew onboard shall sign the written ”seafarers oath” confirming having read and fully understanding the “General Precautions Onboard oil Tanker”

Related Procedures:

“Procedures for Management of Safety and Health Onboard”

“Procedures for Entry into Enclosed Spaces”

" Procedures for Hot Work"

Related articles

Acceptance / rejection of fuel in a quality dispute

Operational guideline during bunkering

Bunker fuel sulfer limit of 3.50 % - Fuel Oil Regulations Frequently asked questions

Ships bunkering guideline- planning, preparation, safety checks & confirmation

Bunkering arrangement and safety factors onboard

Bunkering safe procedure and detail guideline for ships

How to keep bunkering record ?

Safe stability guideline for oil tankers Learn basic procedure

Precautions prior transferring fuel oil into storage tanks

Treatment of waste oil and oily bilge

Bulk liquid cargo handling - Ship to shore safety checklist

Procedure for oil tankers and how to maintain records

Acceptance or rejection of fuel oil

Heating of fuel oil storage tank

Fuel oil viscosity control

Ships bunkering guideline- planning, preparation, safety checks & confirmation

Tanker vessel safety guideline - inert gas system

Tanker vessel safety guideline - gas freeing procedure

Precautions prior entering freezing zone - Check items in oil tankers operation

Tanker vessel safety guideline Check items in oil tankers operation

Tanker vessel safety guideline - how to prevent oil spillage

Tanker vessel safety guideline - tank cleaning procedures

How to ensure safe working atmosphere onboard?

Related Information

General guidance for oil tankers

Tanker equipment and machinery

Pumproom procedure

Pumproom inspection for tankers

Treatment for waste oil or oily bilges

Oil pollution prevention method

General precautions for tankers

Tanker equipment and machinery

General guidance for oil tankers

Crude oil washing for tankers

Other info pages !

Ships Charterparties Related terms & guideline

Stevedores injury How to prevent injury onboard

Environmental issues How to prevent marine pollution

Cargo & Ballast Handling Safety Guideline

Reefer cargo handling Troubleshoot and countermeasures

DG cargo handling Procedures & Guidelines

Safety in engine room Standard procedures

Questions from user and feedback Read our knowledgebase

Home page

ShipsBusiness.com is merely an informational site about various aspects of ships operation,maintenance procedure,

prevention of pollution and many safety guideline. The procedures explained here are only indicative,

not exhaustive in nature and one must always be guided by practices of good seamanship.

Site Use and Privacy - Read our privacy policy and site use information.

//Home //Terms and conditions of use

Copyright © shipsbusiness.com All rights reserved.