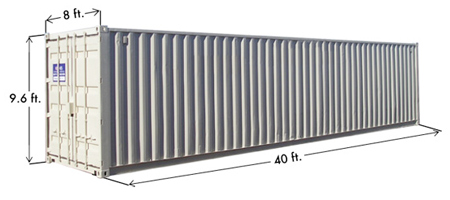

Containers are standardized cargo units. They are manufactured in a large variety of sizes and types, each designed to meet specific cargo and transportation requirements. Their length is usually 20 or 40 feet, although longer containers are used, principally in the US trade; these containers are 45, 48, and 53 feet long.

Their width is always 8 feet, although their height can vary. The term High cube container usually refers to a standard-sized container with a height of 9 feet 6 inches. Container heights can be 8 feet, 8 feet 6 inches, 9 feet 6 inches, or 10 feet 6 inches.

Containers are referred to by the acronym TEUs — 20 foot equivalent units, or 40 foot

equivalent units (FEUs). The ISO standard for containers defines dimensions, both internal and external, and load ratings. All containers have a framework and corner posts fitted with corner castings. The castings at each corner of the container support the weight of the container. The castings are the only points at which a container should be supported, and are used to attach securing fittings, such as lashing rods and twist locks. The position and spacing of corner castings are carefully controlled.

Containers that are longer than 40 feet usually have additional support points at the 40-foot position so that they can be stowed over a standard 40-foot container.

Standard sizes for ISO Series 1 freight containers include those shown in the table below. 20-foot containers are actually a little shorter than 20 feet so that two 20-foot containers can be stowed in a 40-foot bay. The actual dimensions are 12192 mm for a 40-foot container and 6058 mm for a 20-foot container. Thus, two 20-foot containers are 76mm shorter than a 40-foot container.

Container Weight

It has long been a matter of concern that container weights have been inaccurate, guesswork, or deliberately

miss-declared (by up to 20%). Thus it gives rise to serious implications for the stability of ships and, indeed,

road transport and terminal equipment with consequent danger to personnel in all modes of transport.

This concern has resulted in an amendment to SOLAS Chapter VI, Regulation 2, which, from 1 July 2016,

now made it mandatory for all containers to be weighed before they are presented to the ship for loading.

Container weight will be determined by weighing the container after stuffing or by adding the weight

of all contents to the tare weight.

Fig :High Cube Container

20' container

40' container

It will be the shipper's responsibility to weigh the full container or its contents with equipment that

meets certification and calibration requirements. The SOLAS amendment demands that a specific person should

be named and identified as having verified the weight calculation on behalf of the shipper. The verified

gross weight will be declared in a signed document to the shipping company and containers presented

without such a document will not be loaded.

Related Information

- Details Of various Container Types

- Containership operation : Cargo Securing

There are six degrees of motion at sea that a ship may have to encounter in a voyage. However, pitching, heaving, and rolling are three major forces that impact most on a containership's lashing arrangement. Lateral rolling motion factors the greatest challenge for piles of containers. If containers are to be carried safely on the deck of a container vessel, they must be tightly connected to the ship. It is done with the aid of devices known as twist locks.

.....

- Containership operation : Common reasons for stowfall

Container stows often fail due to container stacks being too heavy and too high overall, exposing the lower containers to excessive transverse racking and compressive forces due to the tipping effect. Such an anomaly may occur if the ship is unable to calculate the forces acting on stow with precision. The Cargo/Container Securing Manual is limited in this respect as the examples of container weight distributions shown may not cover all permutations and eventualities. Software programs have the advantage of taking into account all known variables........

- Containership operation: Cargo hold ventilation

Cargo holds ventilation onboard a containership is very important as it minimizes the risk of harm or damage to cargo. A proper ventilation system assures the quality of the transported goods by preventing the formation of condensation in cargo spaces, reducing the harmful heating of the shipment, and removing potential hazardous gases from cargo spaces........

- Containership operation: Safety of personnel

In port stevedores board the vessel for lashing, unlashing and cargo operations and their safety whilst on board is the vessels responsibility. It is important to understand that any injury caused to stevedores or shore personnel due to a condition on board being unsafe, can result in very large claims to the vessel.

.....

- Containership operation: wet damage in cargo hold

When water entered into a ship's cargo, hold it may cause wet damage to the cargo inside containers especially to those stowed on the bottom stack, unless the bilge water is drained in a proper and swift manner. The regular sounding of bilge well or monitoring bilge alarm must be one of the very important or rather essential routine jobs on board. However, this job requires special attention on board. All bilge alarm need to be tested regularly......

- Reefer cargo care at sea

Unlike permanent cold stores or refrigerated ships, where robust equipment is under constant care by qualified personnel, the ISO refrigerated container may travel by several different modes and be in the care of many and varied people. Before being despatched to load refrigerated cargo (usually at shippers' premises), the container and its machinery should be subjected to a rigorous examination.......

- Containership cargo stowage and planning

Master and officers of all vessels require a good working knowledge of the various kinds of cargo they are likely to carry their peculiar characteristics, liability to damage, decay, or deterioration, their measurement, and the usual methods of packing, loading and discharging, stowage, dunnage, etc., as the Master is responsible for the safe loading of his vessel and the proper storage of the cargo......

- Stacking Weights Restrictions

rior loading cargo, stacking weights of containers must be checked against the allowable stack weights on board the vessel both on deck and under deck. Neglecting above may cause serious damage to ships structure, hull and eventually overall stabilty of ship may get affected. Maximum allowable stack weights of Tank tops, Hatch covers and Decks shall not be exceeded at any time......

- Lashing strength calculation

Lashing strength of deck cargo shall be ascertained by using the appropriate lashing strength calculation software where provided. All resulting values for lashing strength must be within the tolerance limits prescribed by the vessels classification society......

- Dangerous goods stowage and segregation

Clear guidelines apply to the stowage and segregation of Dangerous Goods and in some cases may require particular commodities to be carried in completely separate holds. The interaction of two cargoes will not occur if the packaging of that cargo remains intact. However, the Master must always consider the possible effect should the cargo escape for any reason and should not restrict his consideration to those cargoes which are listed in the IMDG Code......

- Reefer Container Stowage

Reefer containers proposed for stowage must be accompanied by a reefer manifest. This reefer manifest should contain Container No., Stow position, Commodity, Temperature, and Ventilation status......

- Out of Gauge Container Stowage

It is essential that, during out of gauge cargo operations, a careful watch is kept for any damage caused to the vessel, her equipment, or to containers. Notice of any damage must be immediately brought to the attention of the Stevedore's representative, the Port Captain/Supercargo and Charterers Agent. Damage reports must be completed in all cases giving the full and comprehensive details of damage caused......

- Special Container Stowage

After receiving stowage plan ships, Chief Officer must ensure that all Deck Officers are aware of any specialized containers due to be worked, such as reefers, vents, over-heights, over-widths, flat racks, etc. and their unique requirements.....

- 20 or 40 or 45 feet Compulsory Stowage Locations

Most cargo securing manual provide a guideline for different container types. These stow positions of 20 feet,40 feet, or 45 feet are also incorporated in a ship-specific stowage planning software and highlight errors if any violations occur......

- Irregular Stowage of Containers

The Terminal Planner shall present the pre-loading plan to the Chief Officer to obtain his approval/comments. The Chief Officer, in turn, enters the cargo data in the loading computer and must ensure that the required criteria, concerning stack weights, trim/stability/stresses/ visibility limitations, DG cargo segregation, and specialized container requirements, are met. He should allow the bunker/freshwater consumption during the voyage and all possibilities of ballasting / deballasting. The completed loading plan must be presented to the ship's Master for approval.....

- Over-stow of Containers

With a closed roof, the hardtop the container offers the same reliable protection as provided by a standard box. Hardtop containers have more lashing points than other container types. This guaran- tees reliable and convenient securing of cargo.

.....

- Hatch Cover Clearance (High cube containers Under Deck )

Hatch cover clearance must be checked carefully in case of loading over height containers or high cube containers underdeck......

- Other matters regarding cargo stowage as necessary

Bulk products carried in a closed container might include malt, grain, seed, polythene granules, chemically inert powders, brake fluid, detergent, fruit juice, wine, non-hazardous oils, sodium silicate, fatty acids and maple syrup amongst many others......

Containerships cargo carrying advantages

Fig:Container ship loaded various container sizes

Other info pages !

Ships Charterparties Related terms & guideline

Stevedores injury How to prevent injury onboard

Environmental issues How to prevent marine pollution

Cargo & Ballast Handling Safety Guideline

Reefer cargo handling Troubleshoot and countermeasures

DG cargo handling Procedures & Guidelines

Safety in engine room Standard procedures

Questions from user and feedback Read our knowledgebase

Home page

ShipsBusiness.com is merely an informational site about various aspects of ships operation,maintenance procedure,

prevention of pollution and many safety guideline. The procedures explained here are only indicative,

not exhaustive in nature and one must always be guided by practices of good seamanship.

Site Use and Privacy - Read our privacy policy and site use information.

//Home //Terms and conditions of use

Copyright © shipsbusiness.com All rights reserved.