Adhere to good seamanship while Handling heavy weights

- Stacking Weights

- Lashing Strength

- Special Container Stowage

- Over-stow of Containers

- Dangerous Cargo Stowage & Segregation

- 20 or 40 or 45 feet Compulsory Stowage Locations

- Hatch Cover Clearance (High cube containers Under Deck )

- Out of Gauge Container Stowage

Cargo Securing Manual (CSM) — The manual required on all types of ships engaged in the

carriage of all cargoes other than solid and liquid bulk cargoes. Cargo units, including containers, shall be loaded, stowed and secured throughout the voyage in accordance

with Cargo Securing Manual approved by the Administration.

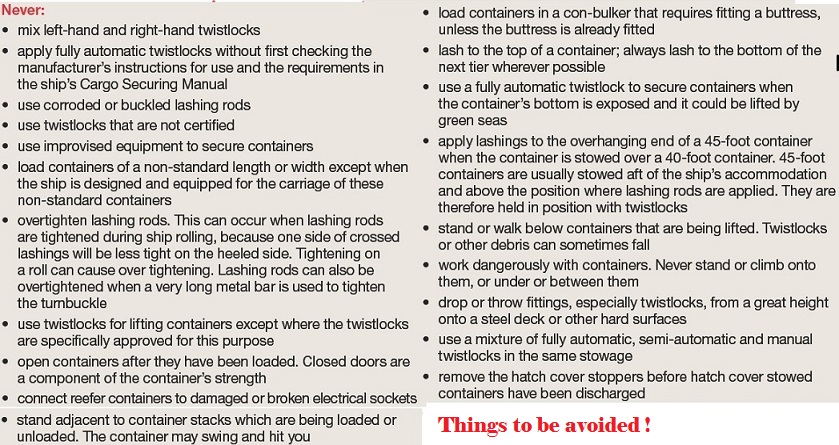

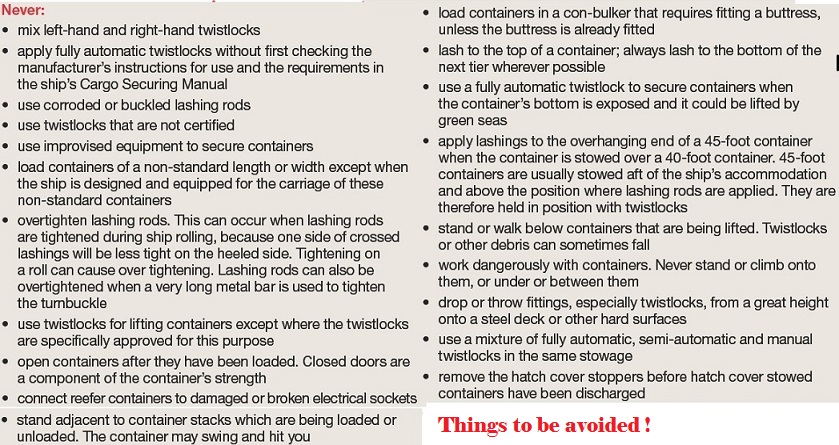

Container handling bad practices - Things to be avoided!

Container handling bad practices - Things to be avoided!

Container handling bad practices - Things to be avoided!