There are several types of containers in everyday use. They all have the same frame, and the differences relate to what they can use and access.

The exterior dimensions of all containers conforming to ISO standards are 20 feet long x 8 feet wide x 8 feet 6 inches high or 9 feet 6 inches high for high cube containers. Some of the most commonly used types are:

Ventilated Container

20'

Ventilated containers are used for cargoes that require ventilation in transit, such as green coffee beans,

hence the units are often referred to as coffee containers. The ventilation galleries along the top and bottom

side rails are designed to prevent the ingress of water, and thus the units can also be used for general cargo.

Ideal for cargo requiring ventilation: Ventilated containers are also known as passive (naturally) ventilated or coffee containers. Ventilation is provided by ventilation openings in the top and bottom side rails. The openings do not let in spray to prevent the cargo's depreciation by rain or spray, for example.

If actively ventilated containers are required, i.e., containers with adjustable ventilation, "porthole" containers may be used, which simultaneously act as insulated or refrigerated containers. For more detailed information, see under Insulated and refrigerated containers.

Lashing rings, to which the cargo may be secured, are installed in the upper and lower side rails and the corner posts. The lashing rings may take loads of up to 1,000 kg. The standard size for ventilated containers is 20'.

Ventilated Container

Fig : Bulk Container

Bulk Container

20'

The dry bulk container resembles a general-purpose container with loading hatches in the roof, doors at

one end, and a discharge hatch either in the end wall or in the doors. It may be used for dry bulk cargoes and

general cargo. Bulk cargo needs a container is placed on a tipping trailer.

Bulk Shipping containers can hold free-flowing dry cargo such as cement, grains, and ores. It is loaded from the top and discharged from the bottom.

Fig :Tank Container

Tank Container

20'

Tank containers are used for the carriage of a wide variety of bulk liquids ranging from edible products,

e.g., fruit juice, wine, and spirits, to hazardous and non-hazardous commodities including liquefied gases.

They may be heated or refrigerated.

Most tanks are owned/operated by shippers and or specialist tank operators and are carried as shipper-

owned equipment. Some carriers provide tanks for specific trades, e.g., Scotch whiskey, rum.

For transportation of liquid chemicals and foodstuffs, Tank containers must be at least 80% full, to prevent dangerous surging of the liquids in transit. On the other hand, they must not, as a rule, be over 95% full, or there will not be sufficient ullage space for thermal expansion. Tank containers intended for transporting foodstuffs must be labeled "Potable Liquids only."

Some hazardous materials must be transported in tank containers with no in- or outlet openings below the surface of the liquid. Steel skeletal framework within which the tank is housed.

Steel framework must have equivalent strength to a dry van box.

The tank has its design and strength criteria, and it may be a pressure vessel.

Tank containers are generally designed for an operating pressure of up to 3 bar (above atmospheric). The test pressure used is 4.5 bar (above atmospheric).

If the cargo requires temperature-controlled transport, tank containers can be equipped with insulation or heating. The temperature of the cargo may be precisely controlled using temperature sensors.

Fig :Dry Freight Container

Dry Freight Container

20' and 40'

General purpose container : The workhorse of the container trades, the dry container is used for those cargoes described as "general",

i.e. any commodity that does not need specialised equipment. Standard dry freight shipping containers are used for multiple purposes ranging from international trade to domestic on-site storage.

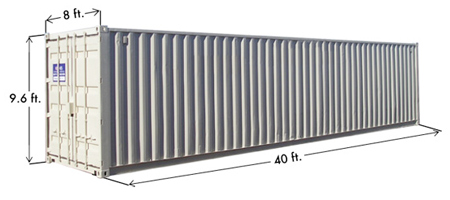

Fig :High Cube Container

High Cube Container

40' and 45'

9'6" High

For over height and voluminous cargo :High-cube containers are similar in structure to standard containers, but taller. In contrast to standard containers, which have a maximum height of 2591 mm (8'6"), high-cube containers are 2896 mm, or 9'6", tall. High-cube containers are for the most part 40' long, but are sometimes made as 45' containers.

Several lashing rings, capable of bearing loads of at most 1000 kg, are mounted on the front top end rail and bottom cross member and the corner posts.

Many 40' containers have a recess in the floor at the front end, which serves to center the containers on so-called gooseneck chassis. These recesses allow the containers to lie lower and therefore to be of taller construction.

Fig :Open top container

Open top container

20' and 40'

It is a unit without a fixed roof but with portable roof supports and tilt or cover for protection from the

weather. Typically used for weighty cargo, cargo that can only be loaded with an overhead crane or for

over-height pieces. Sometimes used as an alternative to a dry container, although care must be taken to

ensure that the cover is properly secured and weathertight.

Removable tarpaulin for top loading of over height cargo

The walls of open-top containers are generally made of corrugated steel. The floor is made of wood.

It has the following typical distinguishing structural features. The roof consists of removable bows and a removable tarpaulin. The door header may be swiveled out.

These two structural features greatly simplify the process of packing and unpacking the container. In particular, it is straightforward to pack and unpack the container from above or through the doors by crane or crab when the roof is open, and the door header is swiveled out.

It should be noted, however, that the purpose of the roof bows of an open-top container is not solely to support the tarpaulin but also to contribute to container stability. Flatracks are therefore more suitable for overheight cargoes.

Lashing rings, to which the cargo may be secured, are installed in the upper and lower side rails and the corner posts. The lashing rings may take loads of up to 1,000 kg.

Usual open-top container dimensions are 20' and 40'.

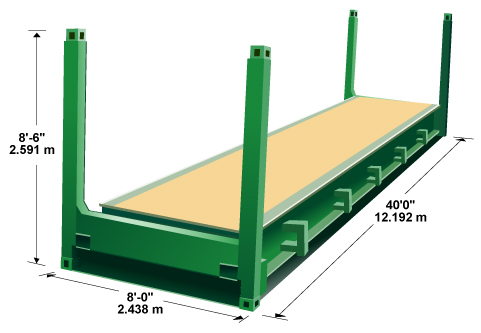

Fig :Flat Rack Container

Flat Rack Container

20' and 40'

A flatrack is a container without side walls but with collapsible end walls or corner posts. Commonly

used for large and or heavy pieces of cargo that can be loaded "in gauge" (i.e., within the dimensions of

the unit) and can thus be handled as a standard unit and incorporated within container stacks ashore and in

cellular holds. A flatrack may also be loaded with "out-of-gauge" cargo, i.e., over-width and or over-height

pieces which require special consideration when planning stowage.

The flatrack is designed for heavy cargoes producing concentrated floor loadings and is usually fitted

with heavy-duty lashing points and slots for side stanchions.

The collapsible end walls or corner posts allow several flat racks to be locked together for empty

handling as a single unit.

Extensively used for over width and heavy cargo. The container frame can be folded flat for ease of transportation when empty.

The structure must have equivalent strength to a dry van box.

P&I cover may not extend to cargoes carried on deck in a flat-rack container.

It is often difficult to secure loads with large dimensions and gross weights. If, for instance, we take a large box or crate containing heavy goods, the package has large, smooth exterior walls that are hardly suitable for attaching load-securing materials. This fact leads to certain demands on the manufacturers of packaging containers to provide additional constructional features that facilitate adequate load securing. It must be noted that not all the components of a package, in particular of a package for heavy goods, are capable of absorbing and maintaining high securing forces.

Half-height

Also fitted with a tilt cover, the half-height container is intended for the carriage of high-density cargoes

such as metal ingots and heavy construction.

Fig :Platform Container

Platform Container

20' and 40'

A platform is the floor of a container with container fittings at each corner but without corner posts. A

platform can only be lifted with a spreader by fitting custom-made wires or chains between the spreader

twist locks and the platform twist-lock pockets. Another unit cannot be stowed above a platform. Thus they

are only suitable for top stowage.

Platforms and flat racks may also be used grouped in a cellular vessel to form a `tween deck for

the underdeck stowage of items too large to be conveyed on a single unit.

They are commonly used for extra length and heavy lift cargo.

Platforms consist solely of a floor structure with extremely high loading capacity; they have no side or end walls. This high loading capacity makes it possible to concentrate heavy weights on small areas. A platform consists of a steel frame and a wooden floor structure.

Platforms are available in 20' and 40' sizes. 40' platforms have a gooseneck tunnel at each end.

Lashing rings, to which the cargo may be secured, are installed in the side rails. The lashing rings may take loads of up to 3.000 kg.

Coil carrier

A derivation of the flatrack with special fittings designed for the carriage of steel coils without the

necessity for heavy tomming.

Fig :Insulated Container

Insulated Container

20' and 40'

For additional insulation of sensitive cargo

This type of container is often referred to not as a refrigerated container but as an insulated container, as it has no integral refrigeration unit. The lack of a refrigeration unit allows such containers to have a larger internal volume and payload than integral units. Onboard, the inside of the container is supplied with cold air via the ship's central cooling plant. The air flows through the container in the same way as in integral units. Cold air is blown in at the bottom, and the "warm" air is removed at the top.

Open-sided

The open-sided container is ideal for cargoes that need to be loaded from the side, e.g., long lengths, and

for cargoes that need ventilation, e.g., fresh vegetables or livestock. Cargo side restraint may be provided by

bars or a metal grill with a canvas tilt cover providing weather protection.

Side-door

This type of container provides side access and the security of an enclosed container. It is ideal for

stuffing or stripping while mounted on a rail wagon.

Fig :Reefer Container

Reefer Container

20' and 40'

The majority of refrigerated containers in use are those with an integral refrigeration unit that plugs into

the ship's electrical power supply. When in a terminal the container is plugged into the shore power supply.

Refrigerated containers are used for the carriage of foodstuffs ranging from chilled fruit and chocolate

to deep frozen meat and fish. Additionally, they are used to carry certain pharmaceutic als and hazardous

cargoes that require temperature control.

Integral Unit (Integral Reefer Container, Integrated Unit): For cooling, freezing, or heating of foods or chemicals.General construction as for dry van boxes.

They usually have their refrigeration unit, with an air or a water-cooled heat exchanger.

A small number of CONAIR boxes use close-coupled ventilation.

They have their data logger to record temperature.

This type of refrigerated container has an integral refrigeration unit for controlling the temperature inside the container. The refrigeration unit is arranged in such a way that the external dimensions of the container meet ISO standards and thus fit into the container ship cell guides, for example. The presence of an integral refrigeration unit entails a loss of internal volume and payload.

Fig :High cube Reefer Container

High Cube Reefer Container

40' and 45'

9'6" High

For over height and voluminous cargo requiring cooling or freezing

Fantainer

The fantainer or fan box is intended for cargoes prone to condensation problems. It is a

general-purpose container, with similar internal dimensions that can be easily converted into a

fantainer. It is located high in the container door hatch and fitted with an extraction fan, which is connected to

an electricity supply when the unit is operated as a fantainer. In this mode, the cargo is stowed on pallets

that form a false floor and create an air duct under the cargo. Air at ambient temperature is drawn into the

floor by the extraction fan through a perforated front sill.

Fig :dry van box Container

Dry Van Boxes

The most common type

They have corrugated steel walls, timber base, steel or glass-reinforced plastic (GRP) top.

Corrugated walls can be made from a plate from as little as 1.6mm (1/16 inch) in thickness.

Their frame consists of side and end rails and corner pillars, fitted with corner castings.

The closed-end is approximately 4.5 times stiffer, in racking strength than the door end.

Garmentainer

Usually, a 40ft high-cube container fitted with internal rails for carrying hanging garments. Care has to be

taken to ensure that the rails are not overloaded, or collapse may occur.

Related topics

2 in 1 container operation in cargo hold

How to load 45 feet containers

Container damage in ''2 in 1'' cargo Operation

Container handling more info pages:

- Definition of various containers in containership

The exterior dimensions of all containers conforming to ISO standards are 20 feet long x 8 feet wide x 8 feet 6 inches high or 9 feet 6 inches high for high cube containers.

Some of the most commonly used types are:Read more......

- Dimensions of various containers

Containers are standardized cargo units. They are manufactured in a large variety of sizes and types, each designed to meet specific cargo and transportation requirements. Their length is usually 20 or 40 feet, although longer containers are used, principally in the US trade; these containers are 45, 48 and 53 feet long.

Read more......

- Containership advantages : In principle they are boxes or containers within a box. These boxes or containers have dimensions of 2.60 x 2.45 m with lengths of 6.10, 9.15 and 12.20 m. Containers are made in steel, aluminium or GRP. They are also of refrigerated design, thus advantageous for long voyages between Australia or New Zealand and the UK. Read more......

- Containership cargo stowage and planning : When considering acceptability of a container cargo stowage plan, the following procedures / guidelines concerning cargo stowage shall be taken into account:

Stacking Weights Restrictions,

Lashing strength calculation,

Dangerous goods stowage and segregation,

Reefer Container Stowage ,

Out of Gauge Container Stowage , ....Read more......

- DG cargo handling - IMDG code guideline :The general provisions for segregation between the various classes of dangerous goods are shown in "Segregation table" (IMDG Code Chapter 7.2.1.16). In addition to the general provisions, there may be a need to segregate a particular substance, material or article from other goods which could contribute to its hazard. Read more......

- How to avoid irregular stowage of containers ? Stowage plan must be checked for any irregular stowage like those mentioned here :

Stacking Weights,

Lashing Strength,

Special Container Stowage,

Over-stow of Containers,

Dangerous Cargo Stowage & Segregation,

20 or 40 or 45 feet Compulsory Stowage Locations,

Hatch Cover Clearance (High cube containers Under Deck ),

Out of Gauge Container Stowage etc.Read more......

- Measures against lashing failure : Lashing strength of deck cargo shall be ascertained by using the appropriate lashing strength calculation software where provided.

All resulting values for lashing strength must be within the tolerance limits prescribed by vessels classification society.Read more......

- Reefer container stowage guideline : Reefer containers proposed for stowage must be accompanied by a reefer manifest. This reefer manifest should contain information regarding Container No., Stow position, Commodity, Temperature and Ventilation status. Read more......

- Care of Reefer container during sea passage :Reefer containers require special care after they are loaded on board ship. These containers need to be supplied with power, monitored closely for proper function and repaired as required in case of malfunction. Read more......

- Container ships procedures for securing for sea :All movable items on deck, inside accommodation and in E/R spaces, including under-deck passages and steering flat are firmly secured. Any unsecured items, in heavy weather, risk not only being damaged themselves, but could also pose a danger to vessel safety by violent contact with sensitive equipment or fittings.Read more......

- Deployment and monitoring of moorings and safety of crew

:The Company’s Risk Assessment procedure shall be utilized to ensure that during all anticipated mooring arrangements and equipment use, the safety of crew is ensured. Read more......

- Cargo securing procedure for container ship :Securing equipment will vary depending on the type of ship but is likely to include;

Twistlocks Lashing bars Turnbuckles Extension hooks Stacking cones (single and double) Twist Stackers Lashing D rings Shoes/Sockets for base twistlocks …Read more......

- Containership operation -Check items upon completion of repair works

: As the nature of container ship operation, it’s tread to be lack of stability, due to Top Heavy Load, the Master shall always take special attention for her stability. Also the Master should remind factors to cause reducing stability more such as Alternating course with Big angle of Rudder, Towing by tugs at the scene of Berthing / Un-berthing, etc. Read more......

- Containership operation -Cargo ventilation requirement : Cargo holds of container ships are fitted with two basic types of ventilation systems, namely natural and mechanical. Mechanical ventilation could be of either the supply or the exhaust type. Read more......

- Containership operation -How to avoid wet damage ?

:Water entered into vessel cargo holds may cause wet damage to the cargo inside containers especially stowed on the bottom, unless the bilge water is drained in a proper and swift manner. Read more......

Other info pages !

Ships Charterparties Related terms & guideline

Stevedores injury How to prevent injury onboard

Environmental issues How to prevent marine pollution

Cargo & Ballast Handling Safety Guideline

Reefer cargo handling Troubleshoot and countermeasures

DG cargo handling Procedures & Guidelines

Safety in engine room Standard procedures

Questions from user and feedback Read our knowledgebase

Home page

ShipsBusiness.com is merely an informational site about various aspects of ships operation,maintenance procedure,

prevention of pollution and many safety guideline. The procedures explained here are only indicative,

not exhaustive in nature and one must always be guided by practices of good seamanship.

Site Use and Privacy - Read our privacy policy and site use information.

//Home //Terms and conditions of use

Copyright © shipsbusiness.com All rights reserved.