Loading & Lashing Requirements for 2 in 1 (Two in One) in a Containership

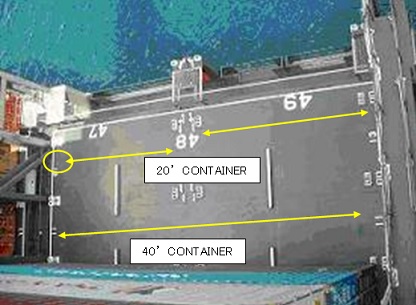

Containership Cargo handling operation involves numerous complexities. To accommodate all container as booked, prevent slot missing, and at the same time for a quick turn around terminal planners often consider loading 2 in 1. The term 2 in 1 operation means when two 20' units loaded in one 40' slots (cell) under the deck.

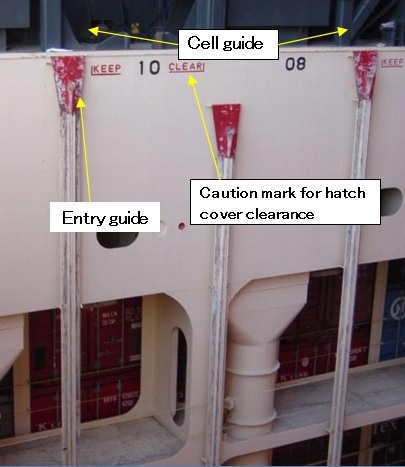

Before doing such a loading operation, the ship's planner should confirm that the terminal staff is aware of the vessel's lashing system. For such a loading under the deck, twist stackers, or equivalent lashing gear generally need. However, it also involves some associated risk of ship structural or cargo damages.

Explained below, two very typical kinds of damages may result from 2 in 1 loading operations if not planned and executed carefully. Firstly, as per the Cargo securing manual, some vessels will require to place sliding base cones at tank top for loading two 20' bottom containers in hold. When changing from 40' stowage to 2 x 20' stowage or vice versa, stevedores will have to go down inside the hold for inserting/removing sliding base cones as required. If sliding base cones are not inserted before loading 2 x 20’ containers, the stack will not be secure and may be liable to shift enroute.

Before doing such a loading operation, the ship's planner should confirm that the terminal staff is aware of the vessel's lashing system. For such a loading under the deck, twist stackers, or equivalent lashing gear generally need. However, it also involves some associated risk of ship structural or cargo damages.

Explained below, two very typical kinds of damages may result from 2 in 1 loading operations if not planned and executed carefully. Firstly, as per the Cargo securing manual, some vessels will require to place sliding base cones at tank top for loading two 20' bottom containers in hold. When changing from 40' stowage to 2 x 20' stowage or vice versa, stevedores will have to go down inside the hold for inserting/removing sliding base cones as required. If sliding base cones are not inserted before loading 2 x 20’ containers, the stack will not be secure and may be liable to shift enroute.