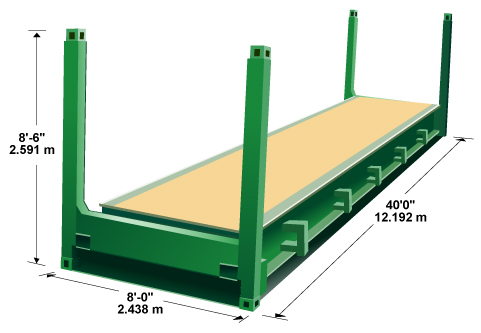

Fig :Flat Rack Container showing

corner castings at each corner

Measures against lashing failure : Lashing strength of deck cargo shall be ascertained by using the appropriate lashing strength calculation software where provided.

All resulting values for lashing strength must be within the tolerance limits prescribed by vessels classification society.Read more......

Reefer container stowage guideline : Reefer containers proposed for stowage must be accompanied by a reefer manifest. This reefer manifest should contain information regarding Container No., Stow position, Commodity, Temperature and Ventilation status. Read more......

Care of Reefer container during sea passage :Reefer containers require special care after they are loaded on board ship. These containers need to be supplied with power, monitored closely for proper function and repaired as required in case of malfunction. Read more......

Container ships procedures for securing for sea :All movable items on deck, inside accommodation and in E/R spaces, including under-deck passages and steering flat are firmly secured. Any unsecured items, in heavy weather, risk not only being damaged themselves, but could also pose a danger to vessel safety by violent contact with sensitive equipment or fittings.Read more......

Deployment and monitoring of moorings and safety of crew

:The Company’s Risk Assessment procedure shall be utilized to ensure that during all anticipated mooring arrangements and equipment use, the safety of crew is ensured. Read more......

Cargo securing procedure for container ship :Securing equipment will vary depending on the type of ship but is likely to include;

Twistlocks Lashing bars Turnbuckles Extension hooks Stacking cones (single and double) Twist Stackers Lashing D rings Shoes/Sockets for base twistlocks …Read more......

Containership operation -Check items upon completion of repair works

: As the nature of container ship operation, it’s tread to be lack of stability, due to Top Heavy Load, the Master shall always take special attention for her stability. Also the Master should remind factors to cause reducing stability more such as Alternating course with Big angle of Rudder, Towing by tugs at the scene of Berthing / Un-berthing, etc. Read more......

Containership operation -Cargo ventilation requirement : Cargo holds of container ships are fitted with two basic types of ventilation systems, namely natural and mechanical. Mechanical ventilation could be of either the supply or the exhaust type. Read more......

Containership operation -How to avoid wet damage ?

:Water entered into vessel cargo holds may cause wet damage to the cargo inside containers especially stowed on the bottom, unless the bilge water is drained in a proper and swift manner. Read more......

Other info pages !

Basic guideline for Container Ship Operation

Tanker vessel safety guideline Check items in oil tankers operation

Questions from user and feedback Read our knowledgebase

Cargo care at sea Precautions to be taken

Reefer cargo handling Troubleshoot and countermeasures

DG cargo handling Procedures & Guidelines

Cargo securing Check items prior departure port

Safe navigation Various factors affecting ships navigation at sea

Hull strength & stability Prior loading how to ensure hull strength & stability of ship

stevedores injury How to prevent injury onboard

Environmental issues How to prevent marine pollution

Safety in engine room Standard procedures

Site Map Page listing for this site.

Home page

ShipsBusiness.com is merely an informational site about various aspects of ships operation,maintenance procedure,

prevention of pollution and many safety guideline. The procedures explained here are only indicative,

not exhaustive in nature and one must always be guided by practices of good seamanship.

ShipsBusiness.com is merely an informational site about various aspects of ships operation,maintenance procedure,

prevention of pollution and many safety guideline. The procedures explained here are only indicative,

not exhaustive in nature and one must always be guided by practices of good seamanship.

Site Use and Privacy - Read our privacy policy and site use information.

Terms and conditions of use

Copyright © shipsbusiness.com All rights reserved.