Most ships are designed to carry a certain amount of cargo at a designated speed, consuming a certain amount of fuel under a specified trim condition. Loaded or ballast, trim has a significant influence on the resistance of the ship through water. Therefore, optimizing the trim can deliver significant savings.

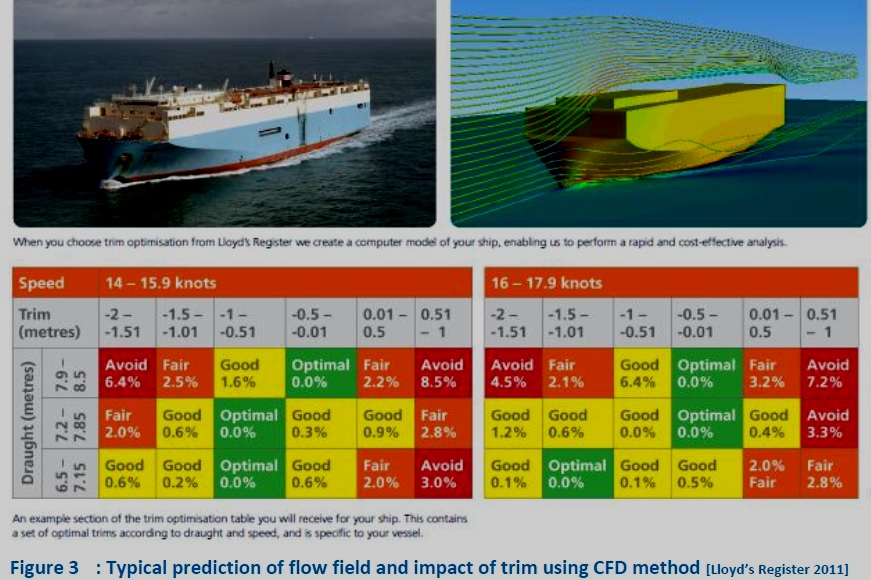

For any given draft and speed, there is a trim condition that gives minimum resistance. Therefore, the optimum vessel trim is a function of draft and speed. A ship's optimum trim may be established as part of routine operations or through tank testing or the use of computational methods. Computational Fluid Dynamics (CFD) methods are used extensively to estimate optimal trim settings for energy efficiency. However, these may require information from ship model tests and full-scale measurements.

Computational Fluid Dynamics (CFD) is a branch of fluid mechanics that uses numerical methods and software systems to solve and analyze problems that involve fluid flows, including liquids and gases. In shipping, it is widely used to estimate ship resistances and improve ship design via a reduced number of trial and error experiments such as ship's model tank testing. CFD methods involve a significant level of numerical calculations, thus high computer powers that are readily available. On-going research and development has yielded much more accurate estimation of a ship's resistance and powering using this technique; including its use for establishing a ship's optimal trim.

Operationally, design, or safety factors may preclude the full use of trim optimization. The possibility of trimming a ship should be seen concerning stability, maneuverability, and other safety and operational aspects. It is the master or chief officer of the vessel that will ultimately ensure all situations are considered.

Economic benefits

Trim optimization has significant economic benefits in terms of fuel savings. These economic benefits will vary from one ship's size and type to others. It should be emphasized that even small trim changes can have a large impact on vessel performance. A 2% to 4% reduction potential in fuel consumption is generally referred to in most literature. However, depending on ship type and operation draft, this number may be higher or lower. Therefore, all possible measures should be tried to ensure that this potential is for energy-saving realized. Sailing just 5-10 centimeters off optimal trim might cause ships to operate at higher fuel consumption levels than normal [Tero Illus, 2012].

There is a bulk of shreds of evidence on significant fuel saving potentials due to trim. Ship resistance is altered due to a vessel's trim through viscous resistance, which is a function of the wetted hull surface area. When trim changes, wetted surface area and thereby hull resistance will be affected. By definition, if resistance increases, fuel consumption, and emissions also increase.

Trim needs to be optimized before and during a ship's voyage through a proper loading of the ship or use of ballast water to achieve a floating position that consumes the least propulsion power. Ships normally record their trim before the voyage by directly reading the draft marks. So, considering that the weight distributions on the ship allow trim adjustment, finding the appropriate and optimal floating position before voyage becomes possible (this is referred to as "static trim" when the ship is not sailing). However, knowing the exact trim and draught during a ship's voyage is important. The trim under operational condition is normally referred to as "dynamic trim" and is different from "static trim" due to the impact of ship

motion. Its measurement requires real-time readings through sensors and relevant onboard data systems.

A vessel with high trim and draught fluctuations (more changes of dynamic trim) during its voyage might benefit more from trim adjustments than those with small fluctuations. The following are two real examples of proven savings by trim optimization:

- Containership Example [Tero Illus, 2012]: This case is for a 5,500 TEU container ship over 136 sea days crossing. It was found that the average percentage of propulsion power loss due to non-optimal trimming was 5%, while the vessel was on long, trans-oceanic legs, although lower on shorter and more coastal routes. The trim-related saving potential was calculated at 350 tons of HFO for the crossing. Even if operational constraints meant that the ship was only able to follow an optimum trim 80% of the time, 280 tonnes of fuel would still have been saved. Such a saving translates into more than US$ 100,000 reduction in bunker costs for the vessel operator in less than five months.

- VLCC Example [Melvin Mathew, 2012]: The results of a study on the impact of trimming on a VLCC showed that VLCCs could benefit significantly from trim optimization due to their size and rate of daily consumption. The saving is dependent on the rate of use of the suggested optimum trim by the crew. It can be influenced by external conditions, such as extreme weather and the crew's commitment to applying the trim guidance given to them. This study showed that proper use of trim adjustments translates into propulsion energy savings of 1.8%, which equates to about 505 tonnes of fuel consumption reduction with saving levels of more than US$ 200,000 annually.

Definitions

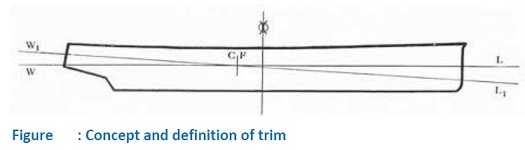

Trim: Trim is normally defined as the difference between the aft draft and the forward draft:

Trim = TA-TF

Where:

TA =

Aft draft (m),

TF =

Forward draft (m)

When the trim is positive, it means that the vessel's stern is more inside the water than forward. Accordingly, positive trim means trim to aft, and negative values of trim means trim to forward. The concept of trim is shown in Figure .

Optimum trim: Optimum trim refers to a ship's trim under which the required propulsive power is minimal for the specific operational speed and a draft of the vessel.

Load planning:

The ship loading plan specifies the loading levels and how the loads should be distributed in different cargo spaces. The load planning should be done by considering corresponding regulations (e.g., load line convention) but above all the ship stability. The process of

loading of a ship is with port's staff and loading superintendents, but the master or chief officer is ultimately responsible for all the loading and unloading operations.

Loading computer:

A loading computer system is a computer-based system for the calculation and control of ship loading conditions for compliance with the applicable stability requirements and longitudinal and local strength requirements. The ship-board loading computer system consists of software (calculation program) and an appropriate computer (hardware).

Even keel refers to ship condition when the draft of a ship fore and aft is the same. In other words, even keel refers to zero trim.

Static trim: This refers to a ship's trim when the ship is in still water (not moving). In this case, the difference between the aft and forward drafts; mainly dictated by the ship's cargo, ballast, fuel on board, etc. distributions.

Dynamic trim: This refers to a ship's trim when the ship is underway and moving. It is different from static trim due to the ship sinkage phenomena.

The sinkage level is characterized by a dynamic sinkage at the forward and a dynamic sinkage at the aft of the ship. Usually, the forward sinkage is more than the aft sinkage and is a function of ship speed as well. Dynamic trim thus is static trim plus trim changes due to ship sinkage while underway.

Physics of trim

A ship's resistances and its trim are closely related to each other. It is because trim could change parameters that impact the hydrodynamic performance of a ship. The high impact of trim on ship performance is well known in particular for container ships and RoRo vessels. Large fuel savings are claimed due to changes to the ship trim.

The possible explanations for the relatively large dependencies of ship performance on the trim could be attributed to the following impacts of trim [Force Technology 2011]:

- Changes to wave resistance

- Changes to wetted surfaces and thereby the frictional resistance.

- Changes to form resistance due to transom submergence

- Changes to various propulsion coefficients including:

i) Resistance coefficients

ii) Thrust deduction

iii) Wake fraction

- Changes to propulsive efficiencies including:

i)Relative rotative efficiency.

ii) Propeller efficiency

On fast container ships and RoRo vessels, there is much to be gained by introducing the correct (optimum) trim. However, a reduction in fuel consumption due to changes to trim might be achieved even on tankers and bulk carriers [Force Technology 2011].

Impact of trim on powering requirement

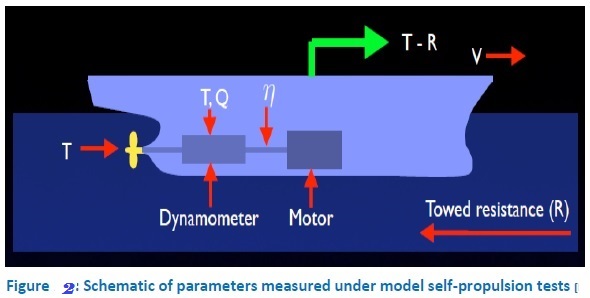

There are different methods of determining a ship's optimum trim. The best results are obtained from self-propulsion tests using a scale model (model tank testing). In self-propulsion tests, not only

the changes in hull resistance are investigated, and the choice of propeller is examined, but also the propulsion coefficients are normally measured. These tests, if performed over a sufficient range of speed and draft, could provide input in identifying optimum trim.

Alternatively, with today's accuracy, trim tables based on the use of CFD software tool calculations can be comparable to resistance model tests. However, both resistance tests and CFD methods tend to ignore the propeller; this may have a significant impact on evaluations of vessels with light drafts.

Figure 2: shows the parameters that are normally measured under self-propulsion tests.

The vessel's loading conditions need to be investigated to find the extreme operational speeds and drafts. A test matrix is then set up, with drafts evenly divided in the test matrix. Typically, the ship is tested at both forward, and aft trims depending on the feasibility of the vessel to undergo those trims. Normally, forward trim is often not possible for the lighter drafts due to restrictions in the propeller's submergence. Also, a simple resistance test under light drafts with aft trim, will not give the correct trim indication as to the effects of the propeller inflow and submergence that makes a positive contribution to performance are not present.

Figure 3: Lloyd's Register shows an example of such a trim guidance table developed using CFD. The ship is converted into a digital model with consideration of both hydrodynamics and aerodynamics. This digital model that resembles the full-scale ship model is trimmed at a variety of ship speeds and drafts, and corresponding fuel consumption is estimated. The fuel consumption is then normalized relative to optimum values to show trims that would lead to high fuel consumption.

Nowadays, the use of CFD for the generation of trim guidance matrices is common practice in the

industry.

Impact of trim on ship powering

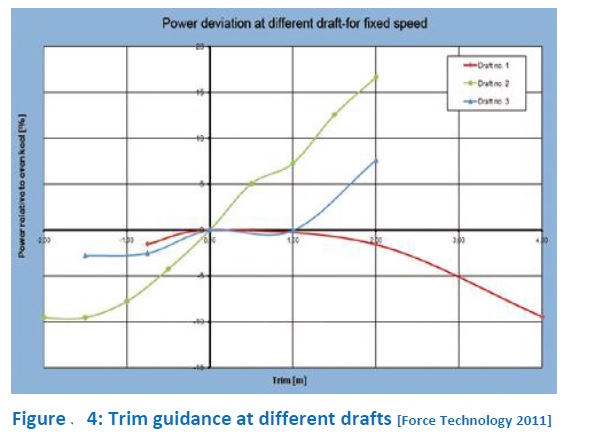

Figure 4 shows the impact of trim on powering for several drafts for a fixed speed. As can be

seen, there are large differences in the impact of trim at different drafts. In this case, the forward trim is better at the deeper

drafts, and the opposite is the case for the light drafts. Optimum trim is often

seen relative to the even keel condition. Here it is important to mention that masters often trim

their ships aft for increased maneuverability.

Referring back to Figure 3 indicates a similar trend. Normally, the ship trim is optimal when trimmed

by the head.

Impact of sea conditions

A frequently asked question is how optimum trim changes with rough sea conditions as compared to

calm water? After a vessel has been evaluated in both calm water and waves, it was seen that sea condition

has no significant impact, and the results for two conditions is the same.

Impact of ship speed

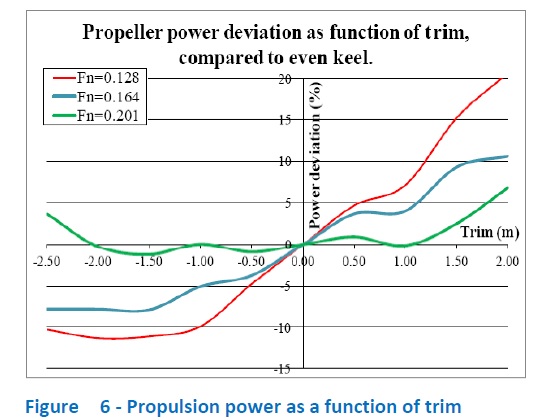

Figure 6 shows the variation of propulsive power as a function of trim and vessel speed

represented by the Froude number. It has been developed for a large cargo vessel that

most of the large car-carriers, Ro-Ro vessels, and container ships [Nikolaj Lamb Larsen 2012]. These ships

usually have a pronounced bulbous bow, slender hull, center skeg, and one propeller.

In this case, at lower speeds (Froude numbers), trim by forwarding gives the best results. As the speed increases, the optimal trim gradually moves closer to even keel (no trim).

Operation guidance

The current industry practice points to the fact that in the great majority of cases, even keel operation (zero trim) is the normal practice. It generally may represent the optimal trim for ships with high block coefficients and non-pronounced bulbous bow (e.g., bulkers and tankers). These ships are not normally operating at very high speeds; thus having a relatively lower wave-making resistance.

The impact of trim on performance could be significant in ships with a slimmer body and higher speed. In particular, the trim may have an impact on the performance of the bulbous bow, thereby making wave-making resistance. It will signify that these types of ships are more sensitive to trim and therefore greater care should be exercised with trim optimization.

With the recent development in energy efficiency regulations, more companies have opted to establish their ships' optimum trims, with the extensive use of CFD capabilities. However, the issue is that all the saving levels given are based on analytical forecasts, and it is challenging to do actual in-operation measurements to confirm the level of fuel savings.

Based on the above facts and for best practice, it is not sufficient to develop a trim matrix and assume that the specified trim guidance will lead to energy efficiency. Practical tests and trials will be required to refine the trim tables. The best way is to use these trim guidance tables while also gathering feedback from masters on their judgment of the trim table and its impact on ship powering requirements. The feedback by masters on best trim for ship handling and powering requirements can help to refine the company best practice in this important area.

In using trim optimization, the following ship types would be given greater consideration:

- Container ships

- RoRo cargo and passenger ships

- RoRo car carriers

As indicated above, in addition to identifying and documenting the optimum trim as a function of ship speed and draft, it is proposed that the experience gained by ship staff on the impact of trim on a vessel's fuel consumption should be gathered in order to improve the ship's "trim matrix." Also, the effective use of the loading computer's capabilities is essential to ensure safe trimming of the vessel with an optimal level of ballast water.

Tools for support

Several tools could be used for this purpose:

CFD methods for trim matrix: The effect of trim on fuel consumption can be measured at the model scale in a towing tank, or simulated at full scale using CFD. Much different speed and draft combinations can be simulated in a time-efficient manner using fully viscous flow description analytical techniques. As a result, a trim matrix or map similar to that shown previously can be specified, where the optimum trim as a function of ship speed and draft are specified. The shipmaster or deck officer would normally follow this as a guide for setting the trim.

Dynamic trimming systems: These systems rely on several signals that are recorded while the ship is underway. The signals provide an indication of the ship's actual trim and some performance aspects of the vessel. Then the system uses analytical or artificial intelligence methods to forecast an

optimum trim. Similar to the "trim matrix," as explained, this makes a good deal of theoretical sense, but the actual effectiveness has yet to be established. Dynamic trim optimization includes collecting and monitoring real-time data of propeller thrust and maneuvering rudder angles, weather conditions, and sea-state. These data are then analyzed constantly, and the optimal trim value is calculated and displayed on a real-time basis to advise the crew onboard.

Loading computers: The change in ship trim is achieved via cargo load planning and a ballasting plan when in port. When underway, the shift of ballast water and fuel between their relevant tanks may be used to adjust trim. During loading, occasionally, there are limitations for achieving optimum trim due to the level of cargo and loading limitations that may not allow additional ballast for a proper trim.

Nowadays, loading computers provide additional functionality for the representation of trim, optimal trim, and also loading options to achieve the optimal trim. Trim linked to a loading computer helps the deck officers to achieve a better loading plan and optimal trim.

Barriers to trim optimisation

The good application of trim optimization can be affected by the following constraints:

- Ship loading: The weight distribution on board must be determined to allow trim optimization. Therefore, adequate communication between ship and port is paramount. As stated above, the loading computers may be effectively used for safe loading as well as for setting the optimal trim.

-

Operational risk challenges: This includes the oversight of bending moments and shear forces when practicing trim optimization. In this respect, it should be noted that not all vessels have real-time stability assessors or calculators onboard. Additionally, danger to cargo in particular for those ships with deck cargos, is also another constraint.

-

Real-time bunker and water transfers onboard: The officers on the watch might have incomplete knowledge of the bunker and water (grey/freshwater) transfers onboard. Therefore, they may not be aware of the effects of such activities on the trim. Again this highlights the importance of shipboard communications between deck department and engine department.

-

Watch changeover: Sometimes the information regarding ballast operations is not passed on during the watch changeover between the crew.

Removing of the above barriers requires a good understanding of the subject and training of shipboard crew and their dedication to best practice and a continuous improvement approach to the problem for long-term sustainable culture of best practices.

Frequently asked questions

How much trim impacts fuel consumption?

There is no clear cut answer to this important question. While the impact of trim is known to be significant under some conditions or for some ship types, there are no hard facts from ships' actual operations on the exact level of savings that may be made using perceived optimal trim. It is because the measurement of savings under real operational conditions is quite difficult to assess. There is ample evidence from model tank tests and CFD analytical methods showing that trim has a significant impact on ship fuel efficiency performance.

How does the optimal trim change with ship speed?

The change in optimal trim with ship speed and draft is through its impact on various types of ship resistances. It is reasonable to find that the optimal trim varies with ship speed and ship draft, but this relationship will vary from ship type to ship type.

Is in-passage ship trim different from the trim set when in port?

It is well known that when the ship trim is set to zero during loading (even keel), the ship will give trim by bow due to the impact of ship speed (due to the ship sinkage phenomena). It means that the trim of the vessel while underway is different from its trim while at berth or waiting.

How in practice is trimming done while a ship is underway?

It is done via a shift of ballast water and bunker fuel, between alternative tanks and possibly shift of water.

Is optimum trim different for loaded versus ballast conditions?

A ship's hydrodynamic performance under loaded and ballast conditions could be significantly different due to changes in the draft and wetted surface area and performance of the bulbous bow. The same is true for trim under loaded and ballast conditions. Therefore, there is a need to have the optimal trim established for various draft levels. Also for ships operating in a variety of loading, and therefore, variety of draft conditions, the optimal trim needs to be established for all the working drafts.

How is the trim set / changed?

The change in ship trim is achieved via the proper cargo load planning and ship ballasting plan. The combination is used to achieve the desirable trim. After the loading is complete, ballast water shifting and, to some extent, bunker fuel shifting between tanks can be used to aid trimming. In any case, it is better that load planning is done by considering the optimal trim as otherwise, it may not be possible to trim the ship properly with the use of ballast water only.

Based on what has been described in this section, the following may be stated:

- Trim could significantly influence ship fuel consumption, with the evidence showing up to 4% of savings.

- Trim impact is the result of changes to ship hydrodynamics and thereby ship resistances.

- For every ship, there is an optimal trim that will give minimal ship resistances and maximize fuel efficiency.

- The optimum trim is a function of ship speed and draft.

- For certain ship types, in particular those with higher design speed, slimmer body, pronounced bulbous bow and flat stern design, trim will provide more impact.

- Optimal trims are established either through extensive model testing or CFD analytical methods.

- To achieve optimal trim, due consideration should be given to ships loading and its load planning.

- Ballast water, and to some extent bunker fuel, may be used to trim the vessel.

- Most loading computers on-board provide functionalities and trim tables to achieve the desirable ship trim.

- It is difficult to measure the actual saving levels due to trim while the ship is underway due to impact of other operational conditions (speed, draft, weather, and sea impacts).

References and further reading

The following list provides references for this section and additional publications that may be used for more in-depth study of topics covered in this section:

1.

Tero Illus, 2012 “Taking the guesswork out of trim”, BIMCO bulletin, V107, August 2012.

2. Melvin Mathew, 2012 “Trim Optimisation”, MarinLink 2012,

3. Force Technology 2011, “Understanding of the physics of trim”, Ship and Offshore Green Tech, 2011.

4. Rod Sampson 2008, “Self propulsion tests”, lecture presentation, Newcastle University, April 2008.

5. Lloyd’s Register 2011, Company factsheet May 2011, www.lr.org

6. Nikolaj Lemb Larsen 2012, “Understanding the physics of trim”, presentation to Green Ship Technology Conference, March 2012.

7. “IMO train the trainer course material”, developed by WMU, 2013.

8. ABS 2013 “Ship Energy Efficiency Measures, Status and Guidance“, http://www.eagle.org

Read more on

Energy efficiency measures -Trim optimization

Energy efficiency measures- Ballast water management

Energy efficiency measures- Causes of Hull roughness and preventive measures

Energy efficiency measures- hull roughness reduction

Energy efficiency measures- propeller maintenance

Energy efficiency measures- engine load management

Energy efficiency measures- fuel management

Energy efficiency measures - ship maintenance requirement

Read more on

Pollution by oil [Marpol Annex I ]

What is toxic releases onboard and associated hazards?

....

How to report in case of an oil spillage onboard

Oil disaster prevention

Handling guideline for oil cargo

Oil pollution prevention method

Related articles

Oil spillage prevention procedure

Pollution by other harmful substances & harmful packaged goods

Pollution by garbage [ Marpol annex V ]

Pollution by sewage [ Marpol annex IV ]

Pollution of air [ Marpol annex VI ]

Prohibition on use of harmful (TBT) anti-fouling paints

Pollution by ballast water

Prevention of pollution while carryiung out overboard maintenance

Environment friendly purchasing

Decommissioning / ship recycling

Environmental awareness

Other info pages !

Ships Charterparties Related terms & guideline

Stevedores injury How to prevent injury onboard

Environmental issues How to prevent marine pollution

Cargo & Ballast Handling Safety Guideline

Reefer cargo handling Troubleshoot and countermeasures

DG cargo handling Procedures & Guidelines

Safety in engine room Standard procedures

Questions from user and feedback Read our knowledgebase

Home page

ShipsBusiness.com is merely an informational site about various aspects of ships operation,maintenance procedure,

prevention of pollution and many safety guideline. The procedures explained here are only indicative,

not exhaustive in nature and one must always be guided by practices of good seamanship.

User feedback is

important to update our database. For any comment or suggestions please Contact us

Site Use and Privacy - Read our privacy policy and site use information.

//Home //Terms and conditions of use

Copyright © 2015 www.shipsbusiness.com All rights reserved.