International Safety Management Code (ISM) specifies the rules and regulations for maintenance management that influence the shipping industry. The ISM Code stipulates that each ship operator is responsible for the ship's safe and pollution-free operation. The ship's hull, machinery and equipment should be maintained and operated following applicable rules and regulations.

The part of the ISM Code on "maintenance of the ship and its equipment" describes in general how ships should be maintained, inspected, non-conformities be reported, and corrective actions are taken. Accordingly, the ISM Code states that the shipping company should establish procedures to ensure that the ship is maintained in conformity with the provisions of the relevant rules and regulations and with any additional requirements which may be established by the company. Based on the ISM Code, it is a requirement that "the company should identify equipment and technical systems that through sudden operational failure might result in hazardous situations."

When implementing a maintenance management system on board a vessel as part of the shipping company's safety management system, it is imperative to define the critical systems and equipment. According to manufacturers or other policies, maintenance instructions should be issued to ensure the uninterrupted and safe operation of them.

On the same ship safety issue, the classification societies are a big player within their classification rules. The primary classification societies gradually support more advanced routines for non-intrusive inspections. These include condition-based maintenance where equipment and machinery systems can receive a specific class certificate of alternative survey arrangement if maintained according to this alternative method. This approach simplifies classification routines for certain specific shipboard equipment and systems, leading to more flexible operation and reduced inspection costs.

Maritime maintenance management

Like any other continuous improvement activity, the senior management has to be committed to providing required resources, competent crew, and a well designed and implemented a maintenance management system to achieve the above objectives onboard.

The fundamental part of the maintenance management system is normally a database that contains a register of all equipment on board that needs to be maintained. This database then populated with maintenance plans, maintenance activities carried out, etc. thus providing not only the requirements and plans for maintenance but also the full history of maintenance activities performed.

Effective maintenance planning is essential for ship operation due to its complexity and the obligations on shipping organizations to comply with specific regulations and requirements, including ISM. Poor maintenance management could reduce the ship's availability, which may, in turn, be reflected in the revenue of the company. Another issue that requires attention is the impact of maintenance on the ship's fuel consumption that is highlighted in this section. It is argued and shown that proper maintenance leads to more energy-efficient ship operation. Thus the requirement for maintenance and energy-efficient operation fully overlaps with each other.

Type of maintenance

Maintenance has different forms, and its application may vary from one company to another depending on their diverse requirements. The shipping company usually chooses the most appropriate maintenance type for various ship's equipment based on its maintenance policy or strategy.

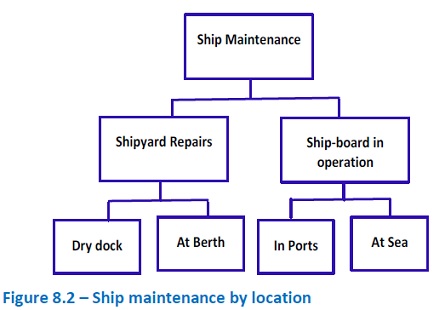

The figure indicates different maintenance types and policy options with an outline description that follows.

Unplanned Maintenance: This type of maintenance is basic and simple as it is defined as breakdown maintenance. In this maintenance policy, the repair or replacement is performed only when a failure occurs. In this type of maintenance policy, however, basic preventive maintenance routines such as lubrication and machine adjustment are applied to the system at regular intervals.

Planned Maintenance: Maintenance scheduling or planning embraces all activities necessary to plan, control, and record all maintenance activities. Planned maintenance is based on a defined schedule of equipment maintenance. This maintenance policy is the standard practice today in the majority of shipping companies. The planned maintenance schedule is decided based on manufacturers' recommendations or use of analytical techniques such as analysis of mean time between failures (MTBF) and reliability analysis. This approach is based on a model of the time that elapses between maintenance periods that takes into account the mechanisms of failures.

Therefore, the planned maintenance schedule is not necessarily based on fixed-time programs but could be based on an analysis method that considers several factors, such as the equipment's reliability characteristics.

Preventive Maintenance: This is a subset of planned maintenance (see Figure 8.1). Preventive maintenance usually depends on the manufacturer‘s recommendations and past experience for scheduling repair or replacement time. In this policy, the maintenance is performed on a planned basis within normally fixed scheduled intervals. Preventive maintenance is thus time-driven in that maintenance is performed based on elapsed time or hours of operation.

The preventive planned maintenance is still the main strategy for shipboard maintenance. The intervals were based upon the manufacturers’ recommendations in addition to past company’s or ship-board experience.

Predictive Maintenance: This is a subset of planned maintenance (see Figure 8.1). This is generally based on what is referred to as condition-based maintenance (CBM) or reliability-based maintenance (RCM). The maintenance decision is based on the current condition or reliability of the system or equipment. This policy stipulates the monitoring of the machinery and acting upon its condition. Usually, engineers record the system parameters, do condition/performance analysis, and use their senses or equipment to hear, sight, and smell the equipment to assess the

system's condition. Different techniques are used in condition monitoring, such as visual inspection, performance monitoring, trend monitoring, vibration monitoring, lubricant monitoring, thermograph monitoring, and acoustic monitoring. The advantages of such a policy are that unnecessary maintenance work can be avoided. In this way, the loss of production during scheduled machine downtime can be reduced, and components can remain in service if it is in good working condition. The industry is gradually moving from preventive maintenance to predictive maintenance.

Reliability Centred Maintenance (RCM): This could be regarded as a subset of predictive maintenance. RCM is a structured way to determine the maintenance requirements of complex systems and assets. It was first developed in the late 1960s, and the approach was derived from the aircraft industry. RCM focuses on the effect of failure with the consequences of a failure being more important than its technical characteristics. The main objective of RCM is to reduce the maintenance costs by focusing on the most important functions of the system and avoiding or removing maintenance actions that are not strictly necessary.

Corrective maintenance: The corrective maintenance may be defined as maintenance, carried out after failure detection. Corrective maintenance can be subdivided into "immediate corrective maintenance" (in which work starts immediately after a failure) and "deferred corrective maintenance" (in which work is delayed in conformance to a given set of maintenance rules). Corrective maintenance is thus a subset of the unplanned maintenance policy.

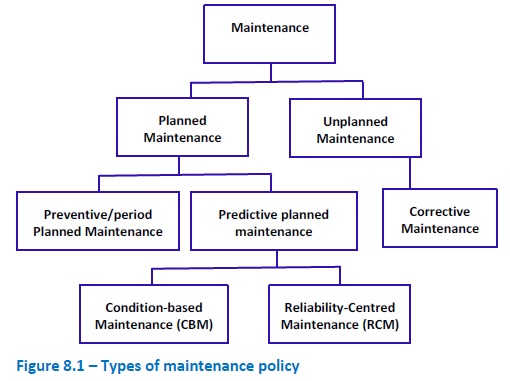

The ship maintenance and repair activities can be completed in two different ways.

- They can be undertaken in the ship repair yard when the ship is due for dry docking for regulatory or class surveys. Certain type of maintenance activities are carried out at shipyard when the ship is at berth.

- Maintenance can be conducted during the ship‘s day-to-day operations of the ship; either while at sea or when in port.

Figure 8.2 shows this way of dividing the maintenance and repair activities.

Prevention Of Pollution While Carrying Out

Overboard Maintenance

Any overboard maintenance must be carried out only after taking permission from port authorities and taking due precautions to prevent any material from falling overboard.

Many port authorities have pollution regulations restricting or forbid maintenance being carried out over the ship's side. This is due to the possibility of potentially damaging substances dropping into the water. Accordingly, Masters must check with the local agent to see what regulations are applicable before planning or carrying out any overboard maintenance.

In ports where such maintenance is permitted, all possible precautions must be taken to avoid polluting the water with paint, thinners, chemical cleaners, loose scale, or other potential contaminants.

Maintenance and energy efficiency

Maintenance operations are fundamental for the energy-efficient operation of machinery and systems. Deterioration of ship systems' condition occurs due to normal wear and tear, fouling, mis-adjustments, long periods of operation outside design envelopes, etc. As a result, equipment

downtime, quality problems, energy losses, safety hazards, or environmental pollution may results. The result is a negative impact on the operating cost, profitability, customer satisfaction, and probable environmental impacts if maintenance is not properly done.

The major challenge of maintenance optimization is implementing a maintenance policy that maximizes the equipment's availability and efficiency, controls the rate of equipment deterioration, ensures safe and environmentally friendly operation, and minimizes the total cost of the operation, including energy cost. Fortunately, most machinery maintenance activities are simple adjustments, cleaning, part replacement, or elimination of adverse conditions, which means preventive maintenance.

Studies by various industries and companies have shown that a company can cut energy consumption at its facility by about 5% to 10% by focusing on its preventive maintenance effort [Terry Wireman 2011]. As indicated earlier, the main strategic aim of a maintenance program is to safeguard the ship's safety and assets and increase the ship's availability for the highest operational returns. Luckily, the excellent maintenance of a ship generally leads to improved performance of the hull, propeller, and machinery, thus providing a more energy-efficient operation.

Hull and propeller cleaning

The impact of hull or propeller fouling and roughness on may affect ship energy efficiency quite significantly. Thus keeping hull and propeller in clean good condition can lead to major energy saving.

Engines’ adjustments and tuning

Engines are the subject of frequent maintenance actions for various reasons; one of the main reasons is the impact of burning low-quality fuel and its impact on engines. Engine condition monitoring is normal practice onboard ship, and engine adjustments and tuning could lead to energy saving.

Mechanical transmission systems

Onboard ships, a variety of mechanical transmissions systems are used. The most complex and important one is the propulsion shafting, and the simpler ones include all the mechanical linkages between drives/motors and the machinery. The energy savings in automatic transmission systems would be influenced by the type of maintenance performed and adjustments made.

For example, the following would influence the energy efficiency of the mechanical transmissions systems depending on the type:

- Shaft and couplings alignment: Any shaft misalignment will not be good for machinery maintenance and transmission energy efficiency. This would lead to further losses in the system in the form of heat.

- V-belt slippage: Improved tension in belt-driven transmissions would prevent slippage during loading on the belt and high loading. This would reduce frictional losses due to slippage.

- Chain and gear misalignment: In chain-driven systems, any misalignment will lead to loss of energy and, at the same time, will not be good for upkeep and maintenance of the system.

- Proper bearing lubrication: Over-lubrication and under-lubrication are not good for energy efficiency. If bearings have excessive lubrication, it may need to churn more of the lubricant,

increasing the lubricant's fluid friction and thus energy losses. The opposite is not desirable as the lack of enough lubrication will increase energy use and lead to more maintenance due to extra wear and tear due to metal to metal contact.

Electrical systems

Like mechanical systems, the energy losses in electrical systems can also be influenced by the state of the system's maintenance. Typical energy losses occur in poor operating conditions for electric motors.

For example, when a motor is fouled with dirt and moisture, this would inhibit the thermal heat transfer process. This condition results in increased wiring resistance, further increasing the motor's temperature and, subsequently, its energy consumption. This could also lead too early failures as compared to a better maintained electric motor. For electric motors, improper or insufficient maintenance on the mechanical transmission system (as explained above) will also increase the amount of energy required by the motor to drive the system.

Steam system

Steam generation systems (boilers) have long been recognized as having the potential to produce substantial energy savings for most plants. There are many items (energy efficiency measures). Most of the relevant EEMs are directly influenced by the state of the steam system maintenance. Examples of such cases are:

- Steam trap maintenance and inspection programs

- Reduced fouling of boilers with direct improvement in its energy efficiency.

- Adjustment of combustion air in relation to fuel flow in boilers (so-called control of excess air). This is part of the performance-related maintenance activities that could yield significant energy savings.

- Leak detection programs for hot water and steam. All leak reductions directly will support the energy efficiency aspects as well.

- Insulation inspection programs to reduce heat losses from the system due to loss of insulation.

- End-use steam optimisation via improved cleaning of the heat transfer surfaces, etc.

All the above measures can only be achieved by an effective maintenance program.

Compressed air system

Compressed air systems can experience similar problems as a steam system such as air leaks, excessive end-use air consumption, and air compressor conditions. Maintenance will look at compressed air production (air compressors) and the compressed air distribution and end-use areas. Aspects to cover include:

- Compressors: Poor maintenance of compressors or incorrect pressure settings would lead to extra running hours and more energy use.

- Air leaks: Any air leakage in the system would require the compressors to run more than necessary. This would lead to additional energy use by the need for compressors to operate for longer periods.

- End-use devices maintenance: The compressed air is used for end-user devices that may have a poor state of maintained. This will lead to extra need for compressed air generation.

The above examples are part of a long list where proper maintenance could support energy efficiency. All of the above require planned or condition-based approaches to maintenance of the compressed air system.

References and further reading

The following list provides references for this section and additional publications that may be used for more in-depth study of topics :

1. Darabnia B and Demichela M, 2013 "Maintenance an Opportunity for Energy Saving" Chemical Engineering Transactions, Vol. 32, 2013.

2. Terry Wireman 2011, "Tips on saving energy using preventive maintenance techniques", http://www.pem-mag.com/Features/Tips-on-saving-energy-using-preventive-maintenance-techniques.html

3. Gösta B. Algelin 2010, "Maritime Management Systems - A survey of maritime management systems and utilization of maintenance strategies," Department of Shipping and Marine Technology, Chalmers University Of Technology, Gothenburg, Sweden, 2010.

4. Yousef Alhouli 2011 "Development of Ship Maintenance Performance Measurement Framework to Assess the Decision Making Process to Optimise in Ship Maintenance Planning" Ph.D. Thesis, School of Mechanical, Aerospace and Civil Engineering, University of Manchester, 2011.

5. "IMO train the trainer course material," developed by WMU, 2013

Read more on

Energy efficiency measures -Trim optimization

Energy efficiency measures- Ballast water management

Energy efficiency measures- Causes of Hull roughness and preventive measures

Energy efficiency measures- hull roughness reduction

Energy efficiency measures- propeller maintenance

Energy efficiency measures- engine load management

Energy efficiency measures- fuel management

Energy efficiency measures - ship maintenance requirement

Related articles

Energy Conservation Efforts

Pollution by oil [Marpol Annex I ]

Pollution by other harmful substances & harmful packaged goods

Pollution by garbage [ Marpol annex V ]

Pollution by sewage [ Marpol annex IV ]

Pollution of air [ Marpol annex VI ]

Prohibition on use of harmful (TBT) anti-fouling paints

Pollution by ballast water

Environment friendly purchasing

Decommissioning / ship recycling

Environmental awareness

Other info pages !

Ships Charterparties Related terms & guideline

Stevedores injury How to prevent injury onboard

Environmental issues How to prevent marine pollution

Cargo & Ballast Handling Safety Guideline

Reefer cargo handling Troubleshoot and countermeasures

DG cargo handling Procedures & Guidelines

Safety in engine room Standard procedures

Questions from user and feedback Read our knowledgebase

Home page

ShipsBusiness.com is merely an informational site about various aspects of ships operation,maintenance procedure,

prevention of pollution and many safety guideline. The procedures explained here are only indicative,

not exhaustive in nature and one must always be guided by practices of good seamanship.

User feedback is

important to update our database. For any comment or suggestions please Contact us

Site Use and Privacy - Read our privacy policy and site use information.

//Home //Terms and conditions of use

Copyright © 2015 www.shipsbusiness.com All rights reserved.